COST – BENEFIT ANALYSIS OF GAUKASTH MACHINE (RAMKALI GAUSHALA- HALALI DAM): IMPACT ON ENVIRONMENT AND FOREST CONSERVATION

Dr SP Singh Dr Sunil Kumar Dr Chitra Prabhat

Key words:

Cost-Benefit, Environmental Benefit, Conservation,

Abstract

This paper is an outcome of the programme conducted by the First author under different training programmes. This paper discusses about the cost benefit analysis of GauKasth machine installed in Gaushalaat Ramkali, Halali Dam, Raisen MP and Other one is at Mugaliachap Village, Bhopal. It involves comparing the total costs incurred in installation with the benefits generated over time. Other than the cost and benefit, the environmental, social and economics benefit has also been observed in in the study area. The objective of this study is, to identify the most cost-effectiveness of the Gaukasth machine, followed by other objectives To reduce the dependence on forest cover and saving trees by replacing Fuelwood with Gau-kasth, To sustain the gaushala by using the cow-dung of more than 2000 cows in the gaushala, To utilise this cow dung by adopting Technology for the GauKasth production, To search out the market for the creating a supply with an aim to earn revenue for sustaining gaushala., To produce and procure dry fodder and husk for the Bovine animals (not productive for villagers to get the milk product), To analysis the cost benefit of Gaukasth machine. How this innovation can be linked withViksit Bharat 2047.

The CB methodology have been used in this study.

The study concludes and suggest how the environmental benefit are helpful in mitigating the impact of climate change, how the fuelwood has been substituted by gaukasth which has resulted in creasing Environmental and forest conservation by saving the depletion of trees. Further, it also suggest that The Replacement of Fuelwood has been reduced where the supply linkages has increased in the Funeral or Samshanghat because of the socio and religious factor and reduces pollution by 30%. The substitute of Fuelwood during Holi festival has also resulted in the increased per capita consumption of Gaukasth instead of fuelwood linked with environment and forest conservation and saving trees every year. The gaukasth has future potential to be used as energy source for generating electricity this will in reducing the use of coal, fossil fuel etc. This innovation and future potential of increased turnover by machine also aligned with make in India, must be replicated in other gaushala for sustaining Livestock population and resulting in sustainable livelihood of people engaged in gau- shala.

INTRODUCTION

This study is an outcome of Three training programme coordinated by the author. This study is field based one till date less literature or no literature is available to document the role of Gaukasth machine on and its impact on Environment and forest conservation. However the first attempt was made by Dr Y K Saxena, Scientist of Central Pollution Control Board to install the first machine at Anarkali Gaushala near Halali Dam near by District Raisen Madhya Pradesh

Some of the work has been done by the first author C B analysis of Professional Education in NRM ( Singh, etal. 2024) Cost-Benefit Analysis of Agroforestry Products ((Singh and Sonali, 2025), However less work has been done in CB analysis of the gaukasth machine.

THIS STUDY DEALS WITH THE FOLLOWING OBJECTIVES:

1. To reduce the dependence on forest cover and saving trees by replacing Fuelwood with Gau-kasth

2. To sustain the gaushala by using the cow-dung of more than 2000 cows in the gaushala

3. To utilise this cow dung by adopting Technology for the GauKasth production.

4. To search out the market for the creating a supply with an aim to earn revenue for sustaining gaushala.

5. To produce and procure dry fodder and husk for the Bovine animals (not productive for villagers to get the milk product)

6. To analysis the cost benefit of Gaukasth machine.

7. Linking this innovation with Viksit Bharat 2047.

METHODOLOGY:

In this paper the Cost benefit method have been used and applied for the agro forestry product. The proposed methodology is based on the spread-sheet model applies the same set of principles used by Gergersen and Contreras. As well as facilitating the usual set of NPV and IRR calculations the spread-sheet model makes it easier to include environmental effects and to take account of financial and Community concerns as well as economic efficiency. Further, a spreadsheet divided into five inter-related sections:

a) the variabies section, containing all the relevant data

b) the market analysis, valuing the project at market prices

c) the proponent analysis, calculating the value of the project to the project proponent

d) the efficiency analysis, calculating the value of the project to the economy

e) the referent group analysis, calculating the value of the project to the community

There are three main formulae used in cost-benefit analysis: net present value, rate of return and cost-effectiveness calculations. This section provides overviews of these methods and the subsequent section deals with the issues of the societal distribution of costs and benefits and the choice of discount rate.

1. NET PRESENT VALUE:

The net present value (NPV) is an overall measure of the difference between the costs and benefits of an intervention. Intuitively, if the intervention contributes more benefits to members of society than the costs it imposes on society, then there is an argument for implementing the intervention. However, the time period in which the costs and benefits are generated or received can vary, so the costs and benefits need to be reduced to a single comparable time period by some method.

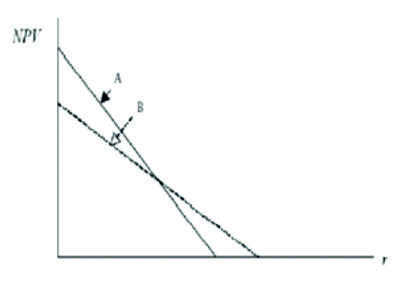

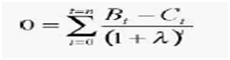

In general terms, given a stream of benefits, BO, B1, B2… and costs CO, C1, C2…, the formula for the net present value (or NPV) is: or, more briefly, where r is the rate of discount and the sub-scripts 0, 1, 2… refer to each time period with 0 representing the start of the intervention. When comparing projects, r should include a premium for the risk and uncertainty associated with predicted future benefits and costs.

If costs are one-off and concentrated in the initial time period (such that C1 = C2 = Cn =0) and the stream of benefits (B) is constant and infinite (n=), then Both benefits and costs need to be reduced to a common denominator, usually money. The investment decision rule is either to invest in all interventions that have a net present value greater than zero, or alternatively to rank interventions according to their net present value.

Net present value (NPV) can only be used in circumstances where the main costs and benefits of an intervention can be reduced to a common unit of account, usually money. This ensures that the value to the participant and society of higher wages, a more rewarding job, less crime and less social dislocation can be monetised in a meaningful way. If the methods used to monetise these effects are not well accepted by policy makers then this method of deciding between interventions should not be used.

RATE OF RETURN:

The rate of return formula uses many of the same assumptions as the net present value referred to above, but instead of calculating a single measure of net benefits at a given discount rate, it estimates the discount rate that is required to produce a single net benefit measure of zero. The rate of return, is derived from the formula:

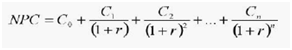

COST EFFECTIVENESS

where t is the time horizon for the intervention. The investment decision rule is to invest in all interventions with an internal rate of return greater than the societal rate of time preference. The latter is the rate at which the average member of society is prepared to forego benefits in the current period, in order to receive benefits in a later period. Cost effectiveness approaches are used when it is not considered meaningful to monetise the benefit streams, and the investment criterion is reduced to ranking the costs of achieving the same goals through different interventions. For example, raising the school retention rate for a target population may be achieved by preschool programs, parent education and awareness programs or direct financial incentives to families. In this case, the investment decision criterion would be to minimise the new present value of costs:

where NPC is net present costs.

To gather the data the interview and group discussion was organised in the gaushala. Both qualitative and Quantitative has been collected from the Group A officer of Environmental accounting: SEEA Framework Visited Ramkali gaushala (halalidam) production unit. This gaukasth is supplied to samshangaht( Funeral ground in Bhopal City-Bhadbhada and Subhash Nagar) This innovation is linked with sustainable management of Environment and substitution of the fuelwood with gaukasth, for forest conservation and protection and saving trees. Leads to Viksit Bharat 2047.

PART-III

ANALYSIS OF COST BENEFIT ANALYSIS OF

GAUKASTH MACHINE

ECONOMICS OF GAUKASTH MACHINE: The impact has been seen in the last 2 years (per gau Shala)

1. Funeral/snaskar of bodies in SamshanGhat: More than 2000 Bodies – per body Fuelwood required is 3 Quintals average. Hence, saved Fuel wood in 6000 Quintals

2. Cost of Fuelwood is 15 RsKG x 6000 quintals, Cost per quintal; – 1500 x 6000 = 90 Lakhs. Rs natural resources has been saved

3. Holika Dahan average per HolikaDahan Fuelwood required is about 3-4 Quintals as per the estimate of Ex-PCCF MP 42 Hectares of forest land lead to degradation/depletion in Madhya Pradesh due to social function, hence this has been replaced by gaukastha.

Cost aspect of machine

1. Manufacturing Cost Rs 60000/- transportation cost from manufacturing Industry to gauShalaRs 5000 = Installation cost Rs 2000/-

2. Variable cost: Electricity bill of 5 hP Motor ( installed in machine)

3. Maintenance cost average Rs 1000

Benefit aspect of machine:

1. Installed capacity of production of machine is 1.5 Tons per day

2. Compressing Wet Cow dung in machine.

3. Converting cow dung in GauKastha.

4. Cost of Gaukasth Per quintal isRs 700 per quintal, means half of the cost of Fuelwood

5. This machine is helpful in attaining the goal of Viksit Bharat 2027, Byminimizing air Pollution by 30% and calorific value is higher than fuel wood.

6. Because of socio- religious value of Cow in Hinduism is very high, helps in preserving Hindu culture

7. The average turnover of each installed machine after deducting variable cost is about Rs 12-15 lakksRs per annum.

8. This turnover over has enhanced the infrastructure development of the main gaushalas located at Mugalia chap village near Bhopal, Ramkali, gaushala,

9. The livelihood of 15-20 families engaged in the gaushala has improved

10. First the gaukasth has also been used to generate /produced 19 Megawatt Electricity

CONCLUSION:

- The study concludes that

- There is a future option of the gau-kasth machine for environment and forest conservation, by utilizing Raw cow-dung and converting it in kasth.

- The Replacement of Fuelwood has been reduced where the supply linkages has increased in the Funeral or Samshanghat because of the socio and religious factor and reduces pollution by 30%

- Due to low cost investment as expenditure some of the funding are required from the funding agencies.

- The substitute of Fuelwood during Holi festival has also resulted in the increased per capita consumption of Gaukasth instead of fuelwood linked with environment and forest conservation and saving trees every year.

- The gaukasth has future potential to be used as energy source for generating electricity this will in reducing the use of coal, fossil fuel etc.

- This innovation and future potential of increased turnover by machine also aligned with make in India, must be replicated in other gaushala for sustaining Livestock population and resulting in sustainable livelihood of people engaged in gau- shala.

ACKNOWLEDGEMENT:

I sincerely acknowledge Officer, Forest department, Villagers and the field visit carried out under different programme, Very difficult to Nib them in Ink of pen Dr Y K Saxena, scientist D, CPCB, New Delhi, Shri Suresh, care taker of Ramkali gaushala.

I also acknowledge, Principal & Patron, Dr. Chitra Prabhat, Govt. Girls College, Katni (MP) for organizing National Webinar- on “Viksit Bharat-2047″Sponsored by- Department of Higher Education Govt. of M.P., Bhopal, Dr. Sunil Kumar Convener and his organizing committee.

REFERENCES:

Subodh Chaware, Sydala Revathi, VVS Prasantha, Vinayak Verma, Vivektripathi, Yaswanthi Kanala, guided by Singh, S.P (2024) Cost-Benefit Analysis of Professional Education in natural resource management, paper presented in the National Seminar on Relevance of Skill Development and Self Reliance India, during 24 December 2024, Sponsored by Department of Higher Education, Govt. of M.P., Bhopal, Organized by Department of Commerce, Jan Nayak Tantya Mama Government College, Bhikangaon, Khargone, M.P.

Singh, S.P. Shreya Sonali (2025), Cost-Benefit Analysis of Agroforestry Products, paper presented and published in Book of Abstract, in National Seminar on “Issues and Challenges of Supply Chain of Agricultural Commodities with Reference to Un-regulated Marketing Channels” Organised by Giri Institute of Development Studies (GIDS) an autonomous institution funded by the Indian Council of Social Science Research (ICSSR) and the Government of Uttar Pradesh. Lucknow, Uttar Pradesh during 26-27 September, 2025.

Authors:

1. Associate Professor, Faculty of Environment and Developmental Economics, Indian Institute of Forest Management, Bhopal

2. Professor, Department of Economics, Government Girls College, Katni, MP.

3. Professor, and Principal Government, Girls College, Katni, M.P.